Selecting the right sandpaper is essential for achieving the best results in any project. Different types of sandpaper cater to specific surfaces and tasks, ensuring efficiency and quality. Here’s an overview of the most commonly used types:

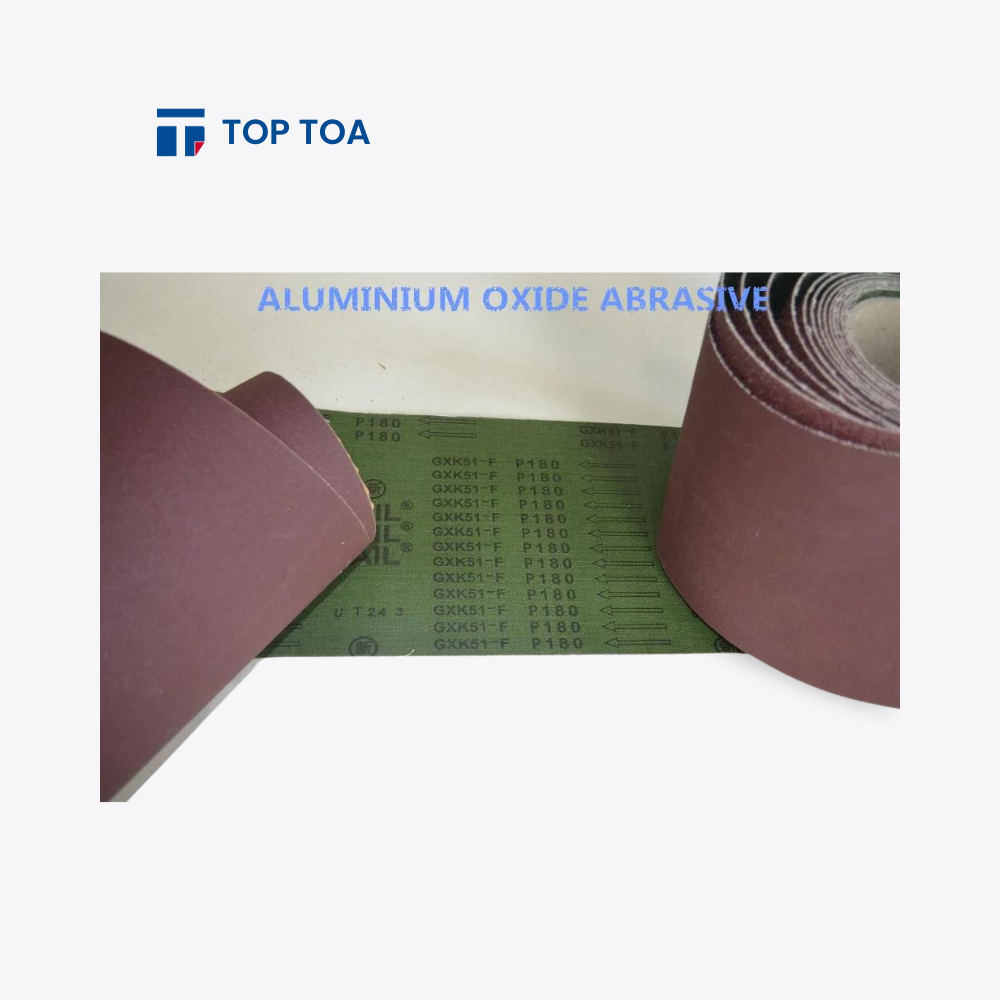

Aluminum Oxide Sandpaper

Durable and versatile, aluminum oxide sandpaper works well on both wood and metal. Its self-renewing surface ensures a longer lifespan, making it a popular choice for industrial and general-purpose sanding.

Ceramic Sandpaper

Tough and efficient, ceramic sandpaper is ideal for heavy-duty applications, such as sanding hardwood or metal. Its aggressive cutting power handles high-pressure tasks with ease.

Silicon Carbide Sandpaper

Known for its sharpness, silicon carbide sandpaper is excellent for harder materials like glass, stone, and metals. It also excels in wet sanding applications, delivering a smooth and polished finish.

Abrasive Sanding Sponges and Blocks

These flexible tools conform to curves and edges, making them ideal for detailed sanding tasks. They’re widely used in automotive, plastic, and intricate woodworking applications.

Why Choosing the Right Sandpaper Matters

Each type of sandpaper has unique properties that make it suited to specific tasks. Understanding these differences allows you to choose the right product for your project, saving time, improving results, and reducing material waste.

How Sandpaper Grits Vary Across Industrial Applications

The grit size determines how coarse or fine the abrasive surface is:

- Coarse grits (40-80): Suitable for heavy material removal in construction and renovation.

- Medium grits (100-120): Often used in woodworking for initial smoothing.

- Fine and very fine grits (150-240): Best for finishing and preparing surfaces for painting or coating in industries like furniture and cabinetry.

- Extra fine and ultra-fine grits (320-1000+): Ideal for polishing and creating high-gloss finishes in automotive and metalworking.

If you’re still unsure which grit size is best for your specific industrial needs, check out my previous blog post on sandpaper grit sizes. It provides a comprehensive guide to understanding the range from coarse to ultra-fine grits and how to select the right one for your project. Whether you’re in woodworking, metalworking, or construction, choosing the right grit is essential for achieving the perfect finish.

Top Toa Industries Sdn Bhd

Reach out today to discover the ideal sandpaper grit for your needs!